Shipping containers, ubiquitous features in the world of transportation and logistics, carry a plethora of goods across the globe, making the modern world’s exchange of goods possible.

Yet, the dimensions of these metal boxes are seldom considered outside of industry professionals. A deeper look into this topic reveals a world of standardization but also adaptability, where the dimensions of these containers play a critical role not only in holding and transporting cargo, but in influencing the overall efficiency of goods transportation.

Whether it’s the universally recognized 20-foot or 40-foot containers or the factors that manipulate the standard sizes to meet the demands of multiple industries, understanding these dimensions gives us a clearer insight into the realms of shipping, storage, and transportation.

Standard Shipping Container Dimensions

An Overview of Standard Shipping Container Dimensions

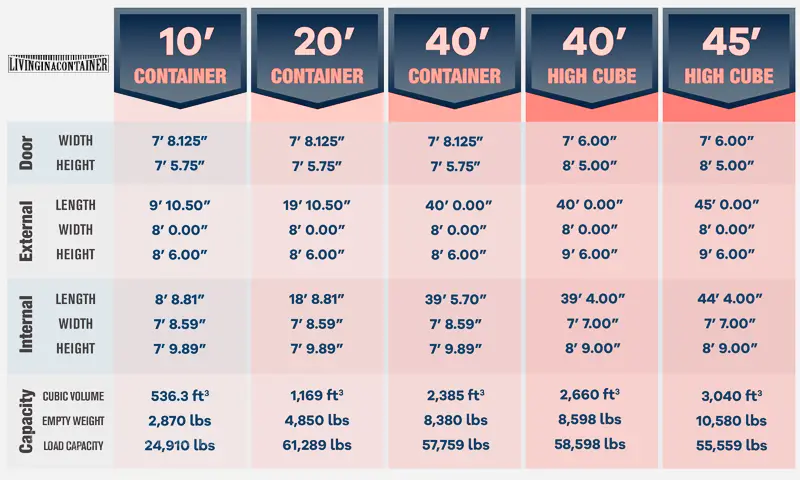

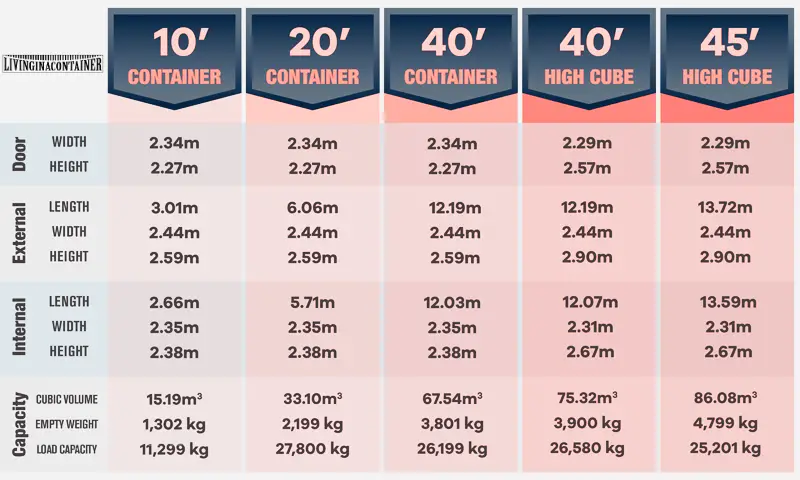

Available in numerous dimensions, the most prevalent sizes of shipping containers are the 20-foot and 40-foot variants.

The usual measurements for a typical 20-foot shipping container are 20 feet in length, 8 feet in width, and 8.5 feet in height external dimensions.

The internal dimensions slightly reduced due to the thickness of the container walls, measuring approximately 19.4 feet in length, 7.8 feet in width, and 7.10 feet in height. This results in a total capacity of around 1,170 cubic feet.

A 40-foot shipping container, frequently used for larger or bulkier shipments, has external dimensions of 40 feet in length, 8 feet in width, and 8.5 feet in height.

The internal measurements are around 39.5 feet in length, 7.8 feet in width, and 7.10 feet in height providing nearly 2,390 cubic feet of space.

Regardless of their size differences, both varieties of shipping containers are structured to be easily stacked and transported, while also being robust enough to safeguard the contents from damaging conditions during transport.

The standardized specifications of these containers ensure compatibility with worldwide infrastructure, from roads and railways to container ships.

Factors Influencing Shipping Container Dimensions

Understanding Factors Influencing Shipping Container Dimensions

The dimensions of shipping containers are largely influenced by their intended usage.

For instance, if a shipping container is designated for storing bigger equipment, like trucks or tractors, the dimensions would need to accommodate the shape and size of these items.

This leads to a variety of container sizes, including 10, 20, 40, and in some cases, 60-foot containers.

The chosen transportation method is another influential factor, as different transport mediums like sea, rail, or truck have varying size requirements and restrictions for containers.

Intermodal shipping, which involves multiple modes of transportation, might need smaller, versatile containers.

On the other hand, for international sea shipping, larger standard-size containers are often chosen due to their increased loading efficiency.

The type of cargo also significantly impacts the size and design of the containers.

Some items require specific packing methods or atmospheres; for example, refrigerated containers, used for shipping perishable items like foodstuffs or biological materials, are designed to sustain certain temperatures and are often larger with distinctive dimensions to house cooling units.

Similarly, containers transporting hazardous materials, such as chemicals or inflammable substances, are uniquely designed with safety considerations.

Therefore, the specific requirements of diverse industries and different types of shipments have a tremendous impact on the dimensions and design of shipping containers.

Interpreting Shipping Container Dimensions

Unraveling Shipping Container Dimensions

The dimensions of shipping containers are a key aspect that determines the volume of cargo that can be loaded, the weight it can bear, and how efficiently they can be stacked.

These dimensions, generally expressed as length, breadth, and height in feet, are typically standardised into two sizes, 20-ft and 40-ft. However, expect slight variations based on different manufacturers’ specifications.

The external dimensions of a container consist of its measurements externally. These measurements are integral when planning for transportation or storage because they determine the number of containers a ship can carry or how many could fit into a warehouse.

Conversely, internal dimensions underline the storage space within the container, consequently influencing how much goods can be stowed away inside.

It’s imperative to remember that the thickness of the container walls occupies some of the internal space, which should be considered while figuring the cargo capacity.

Effect of Dimensions on Loading and Stacking

The dimensions of a container also determine its loading capacity and maximum cargo weight. The more voluminous the container, the greater the number of goods it can carry.

However, the weight of the cargo must not exceed the container’s maximum load capacity, which includes the container’s own weight.

Overloading a container can cause safety issues during transportation and handling.

Stability is crucial when shipping containers are stacked on top of each other, either for storage or during transit.

The container dimensions, specifically their uniform lengths and widths, enable secure stacking, optimizing space utilization.

The height and weight of the containers also play a vital role in deciding the maximum stack height.

Typically, care must be taken to ensure that the stacked containers do not exceed allowable height clearances and weight limits for the transport medium, whether on sea or land.

Unraveling the mystery around shipping container dimensions, it becomes evident that these seemingly simple structures are designed and engineered with careful precision.

They have to be adaptable enough to cater to different types of cargo while maintaining a standard that allows for efficient stacking, storing, and transportation globally.

The flexibility of these dimensions speaks to the value and importance of these containers in our everyday life, quietly facilitating the global exchange of goods we often take for granted.

They indeed form a strategic link in our global supply chain system, emphasizing the remarkable scope of human ingenuity and its inclination towards standardization for increasing efficiency.